Pipe Blasting

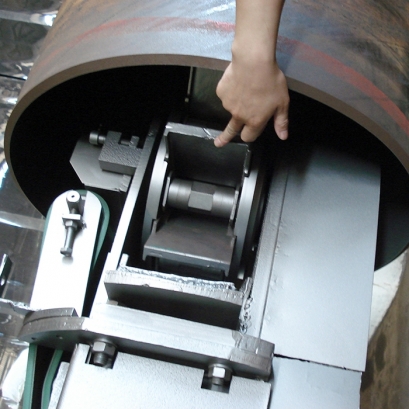

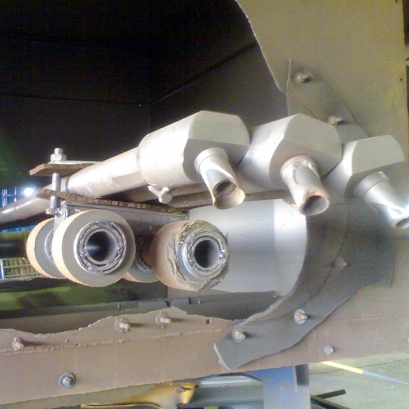

PAXAA designs & manufactures fully automated Pipe blasting machines for surface preparation, profiling, removing dust & mill scale from steel pipe.

The purpose for pipe blasting is to prepare or clean the steel surface or substrate for subsequent protective coatings applications such as pre-treatment for painting, tar or PE coating, using (predominantly) steel grit & shot blast media to achieve the desired cleanliness and anchor profile required to achieve acceptable coating adhesion. Depending upon the coating specifications required, 40-100 micron surface profile depth can be easily performed. Pipes can also only be blast cleaned alone, immediately prior to load out removing the majority of internal surface corrosion prior to pipe welding either on or offshore.

PAXAA pipe machines include an air wash and dust collection system that work together to remove contaminants and fines, control dust and maintain correct abrasive size.

PAXAA works with customers to determine the requirements and will consider many factors, including:

- Steel abrasive types

- Profile requirements

- Surface cleaning requirement

- Line speed requirement

As well as working closely with coating manufacturers to assure proper mill profile is achieved to give the best adherence of coating.

All PAXAA systems are capable of a standard cleanliness value of SIS S.A. 2.5/ ISO 8501-1, SSPC-SP 10/ NACE No.2, near white metal cleanliness, or a SIS S.A. 3/ ISO 8501-1S, SSPC-SP 5/NACE No. 1, white metal cleanliness, when required for certain applications / specifications.