Universal Mill

UNIPAXX AT A GLANCE

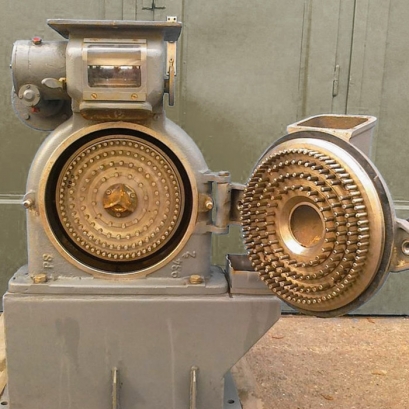

If you looking for a versatile grinding machine which is capable of handling different types of bulk materials the answer to your demand would be the PAXAA Universal Mill, Unipaxx. The mill is designed to be fitted with interchangeable grinding elements to handle a range of soft to medium-hard materials, providing the advantages of customized grinding in one single housing.

DESCRIPTION OF UNIPAXX

OPERATION OF UNIPAXX

The feed flows from a volumetric feeder by gravity through the Unipaxx's inlet, which directs the feed into the grinding chamber's center. The grinding tool (or tools) rotates at high speed, creating centrifugal force that accelerates the feed particles outward. The particles high-speed outward flow hurls them against the pins, blades, or other elements at the tool's periphery. The particles' impact with these elements and other particles fractures and reduces them. With disk grinding tools, desired-size particles exit the disk periphery and flow toward the mill's bottom outlet. With other grinding tools, the reduced particles pass through the bars or blades to the stator. After exiting the mill, the particles fall by gravity or are drawn by a pneumatic conveying system to downstream processing or storage.

MILL SELECTION

Base your selection of the PAXAA Universal Mill's components and features, including grinding tools, stators, and construction materials, on your feed and final product requirements. During the selection process, expect to work closely with PAXAA. You may be asked to describe the characteristics of each of your feeds - including

If you looking for a versatile grinding machine which is capable of handling different types of bulk materials the answer to your demand would be the PAXAA Universal Mill, Unipaxx. The mill is designed to be fitted with interchangeable grinding elements to handle a range of soft to medium-hard materials, providing the advantages of customized grinding in one single housing.

DESCRIPTION OF UNIPAXX

- It can grind feed materials of up to 3.5 Mohs hardness

- Its applications include pharmaceuticals, chemicals, fertilizers, cosmetics, food products, animal feeds, and mineral powders

- It accepts feed materials with an average particle size typically up to 50 mm; a large mill can handle materials up to 100 mm

- The resulting final average particle size can range from fairly coarse to as fine as 20 microns

- To grind heat sensitive materials such as resins, the mill can be equipped with a grinding tool that generates high airflow and a wide housing that enlarges the grinding chamber and dissipates the grinding heat

OPERATION OF UNIPAXX

The feed flows from a volumetric feeder by gravity through the Unipaxx's inlet, which directs the feed into the grinding chamber's center. The grinding tool (or tools) rotates at high speed, creating centrifugal force that accelerates the feed particles outward. The particles high-speed outward flow hurls them against the pins, blades, or other elements at the tool's periphery. The particles' impact with these elements and other particles fractures and reduces them. With disk grinding tools, desired-size particles exit the disk periphery and flow toward the mill's bottom outlet. With other grinding tools, the reduced particles pass through the bars or blades to the stator. After exiting the mill, the particles fall by gravity or are drawn by a pneumatic conveying system to downstream processing or storage.

MILL SELECTION

Base your selection of the PAXAA Universal Mill's components and features, including grinding tools, stators, and construction materials, on your feed and final product requirements. During the selection process, expect to work closely with PAXAA. You may be asked to describe the characteristics of each of your feeds - including

- material type,

- particle size distribution,

- bulk density,

- flowability,

- abrasiveness,

- temperature sensitivity,

- moisture or volatile content, and

- chemical corrosiveness.