HEPAX Classifier New

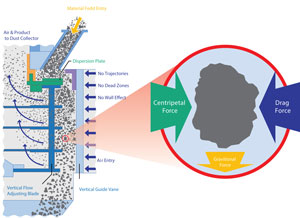

The PAXAA HEPAX Classifier represents a highly versatile, energy-efficient system for the consistent separation of particles in 6-150 micron range. This separator has a compact design requiring minimal space for installation. Its simple circuit layout allows the highly flexible separator to be applied in a variety of systems and to fit any new process requirement or existing system. Installation time for the separator is minimized by its bolted-flange design.

- Optimized and better separating efficiency over 1st & 2nd generation separators

- Compact design allows easy retrofit into existing facilities

- Saves on operating expenses on Low energy consumption

- Durable, wear-resistant design minimizes maintenance

- Consistent, high-quality product, regardless of variations in feed material, through easy-to-make changes in air flow and variable-speed rejector cage

- Wear protection targets specific abrasion mechanisms for each separator component

- Energy savings of the grinding plant with a fineness of separation up to 40%

- Direct Drive Coupling

- A cartridge containing all bearings guarantees a long lifetime and protection against dust

- Easy accessibility to all separator parts

- Complete protection against wear

- Reliable lubrication system

- Processes abrasive materials: ceramic liners and/or inexpensive, wear area replaceable liners available

- Fines collected in cyclone or process collector

- Control Panel

- Smooth V-Belt Transmission

- Central lubrication system and bearing supervision

- Effective product cooling or temperature control system

- Drying within the separator: Both oven exhaust gases and hot gases from a hot gas producer or a mixture of gasses can be used Instead of the separation air & fed into the separator

- Non-standard paint finish

- Support Structure

- Handrails, Ladder and platform

The coarse material doesn't enter in the rotating cage and goes out by gravity up to the bottom device (cone or other). The fine material enters in the cage and exits with the air flow by the upper or lower part of the separator.

Aggregates, Bicarbonate, Blast furnace slag, Cement, Ceramics, Chemicals, Coal, Crushed stone, Diatomaceous earth, Feldspar, Ferro-silicon, Fly ash, Food products, Gabbro, Granite, Gypsum, Hydrated lime, Iron ore, Lime, Limestone, Minerals, Petcock, Plastics, Quartz sand, Raw meal, Sand & Gravel, Shredded fibers, Silica sand, Soda ash, Trap Rock, ...